Tire News & Information

Free shipping

Best price guarantee

SimpleCrew exclusive savings

0% financing options

Tire replacement coverage

24/7 roadside assistance

Easy returns

Many equipment owners face constant frustration with flat tires that disrupt their work and require frequent maintenance. Semi-pneumatic tires offer a practical solution that eliminates the hassle of air pressure checks and puncture repairs.

These specialized tires combine the cushioning benefits of air-filled designs with the reliability of solid construction. Unlike traditional pneumatic tires that depend on pressurized air, semi-pneumatic options use a unique structure that maintains its shape without inflation.

The technology behind semi-pneumatic tires makes them increasingly popular for wheelbarrows, lawn mowers, hand trucks, and various industrial applications. Understanding how these tires work and their specific advantages helps equipment owners make informed decisions about their tire needs.

What Are Semi-Pneumatic Tires?

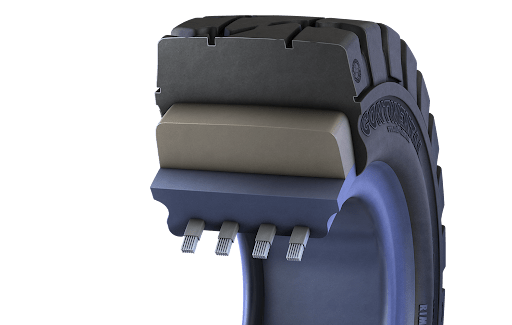

Semi-pneumatic tires represent a clever engineering solution that bridges the gap between solid and air-filled tire designs. These tires feature a thick rubber exterior with hollow cavities or air pockets molded directly into the tire structure. The trapped air provides cushioning without requiring any pressurization — the tire maintains its shape through the strength of its sidewalls rather than internal air pressure.

The construction differs fundamentally from traditional pneumatic tires that need regular inflation to specific PSI levels. While a pneumatic tire relies on pressurized air to support weight and provide shock absorption, semi-pneumatic tires achieve similar benefits through their structural design. The sidewalls are engineered to be thick and sturdy enough to support the intended load without collapsing, even when the internal air pockets contain no pressure at all.

This unique design means semi-pneumatic tires cannot deflate like regular tires. The air trapped inside the hollow cavities stays there permanently, sealed within the rubber during the manufacturing process. Even if the tire sustains a puncture that would instantly flatten a pneumatic tire, a semi-pneumatic tire continues to function normally because its performance doesn't depend on maintaining air pressure. The structural integrity comes from the rubber itself, making these tires remarkably reliable for specific applications where consistent performance matters more than maximum comfort or shock absorption.

How Do Semi-Pneumatic Tires Compare to Other Tire Types?

Semi-Pneumatic vs Pneumatic Tires

Pneumatic tires, filled with air, excel in providing a smooth ride due to their ability to absorb shocks effectively. However, they require frequent maintenance—regular air pressure checks and puncture repairs can become tedious. This maintenance is essential to prevent flats and ensure optimal performance.

Semi-pneumatic tires bypass these issues entirely. Their design includes sealed air pockets, which offer a degree of cushioning without the need for inflation. This makes them an excellent choice for environments where reliability is crucial, as they won't go flat and require less upkeep compared to pneumatic options.

Semi-Pneumatic vs Solid Tires

Solid tires are known for their extreme toughness and ability to handle heavy loads without damage. They are completely rigid, which often results in a harsher ride, as there is no built-in flexibility to absorb impacts.

Semi-pneumatic tires provide a more balanced solution. While they maintain the durability necessary for demanding applications, their internal air pockets allow for some shock absorption. This balance makes them well-suited for tasks where both resilience and a smoother ride are desired.

What Are the Main Benefits of Semi-Pneumatic Tires?

Puncture Resistance

Semi-pneumatic tires thrive in challenging environments with debris and sharp objects. Their design means they don't rely on air, so they remain unaffected by typical punctures. This resilience makes them ideal for areas where sharp obstacles are unavoidable, ensuring uninterrupted operation and reliability.

Low Maintenance Requirements

These tires simplify upkeep by eliminating the need for air pressure checks. With no air to monitor, there's no need for valves or the potential for leaks. This straightforward maintenance approach allows users to focus more on productivity without the usual tire-related concerns.

Cost-Effectiveness

Offering a cost-efficient option, semi-pneumatic tires often come as complete wheel sets, reducing initial expenses. The absence of ongoing maintenance needs lowers long-term costs. Their affordability and simplicity make them a smart choice for those looking to manage budgets effectively.

Durability

Engineered for longevity, semi-pneumatic tires use robust materials that stand up to extensive use. Their design supports weight effectively without air, providing consistent performance. These tires maintain their integrity under heavy loads, making them a dependable choice for demanding applications.

Where Are Semi-Pneumatic Tires Commonly Used?

Semi-pneumatic tires are versatile, finding applications in settings where dependable performance and reduced downtime are vital. They serve well in environments prioritizing continuous functionality over high-speed performance.

Lawn and Garden Equipment

These tires are ideal for garden tools like push mowers and utility carts. Their design navigates outdoor surfaces smoothly, handling typical garden debris effortlessly. With their solid construction, they offer a worry-free experience for home gardeners and landscapers alike.

Material Handling and Mobility Devices

In industrial settings, semi-pneumatic tires are used in equipment like hand trucks and warehouse carts. Their resistance to punctures and ability to handle tough conditions make them suitable for demanding tasks. For mobility aids such as wheelchairs, they provide consistent reliability without the need for frequent maintenance checks.

Children's Toys and Industrial Applications

Children's bicycles and ride-on toys benefit from the tire's robust design, allowing for safe and uninterrupted use. In factories, these tires support industrial castors, ensuring that heavy machinery and equipment move smoothly. Their strength and durability make them an excellent choice for environments that require steady, reliable operation.

What Should You Consider About Semi-Pneumatic Tire Features?

Evaluating the features of semi-pneumatic tires is essential to ensure they meet your equipment's specific demands. These aspects influence their effectiveness and adaptability.

Tread Patterns

The tread design of semi-pneumatic tires affects their performance in different environments. For outdoor tools, a rugged tread enhances grip and stability on uneven ground. Smooth treads are ideal for indoor equipment, providing seamless movement on flat surfaces. Choosing the right tread pattern for your needs maximizes efficiency and ensures the tire performs optimally in its intended setting.

Weight and Portability

Semi-pneumatic tires are designed to be lightweight, offering ease of handling and transport. This feature is particularly beneficial for equipment that requires frequent relocation, minimizing effort and enhancing maneuverability. Compared to heavier solid tires, these tires ensure that moving and operating equipment is less labor-intensive.

Mounting Options

Installation and maintenance of semi-pneumatic tires are simplified by user-friendly mounting systems. Often equipped with single-bolt setups, they allow for quick and easy attachment. Many of these tires come pre-mounted on plastic wheels, facilitating swift replacements and reducing downtime, ensuring consistent operation with minimal hassle.

Are Semi-Pneumatic Tires Right for Your Equipment?

Best Applications

Assessing your equipment's needs involves considering where and how it's used. Semi-pneumatic tires thrive on smooth surfaces, making them perfect for indoor settings or light outdoor tasks without challenging terrains. They provide a dependable option for environments where unexpected tire issues could disrupt workflow, ensuring steady performance.

For cost-effective operations, these tires stand out due to their minimal upkeep and attractive pricing. Their robust design and resistance to typical hazards make them suitable for areas where continuous operation is essential, such as workshops and light industrial applications.

Limitations to Consider

While these tires offer several benefits, acknowledging their constraints is important. They lack the higher shock absorption found in fully pneumatic tires, which might limit their effectiveness on rough or uneven surfaces. Without the option to adjust firmness, they may deliver a ride that's firmer than some users prefer.

These tires aren't designed for extreme conditions or high-speed use. If your equipment often faces challenging surfaces or demands maximum comfort, exploring alternative tire types could better meet those needs.

Making Your Decision

Deciding on semi-pneumatic tires requires evaluating your typical terrain and operating conditions. Consider your willingness and ability to handle tire maintenance. Weigh the total cost of ownership, including potential savings from reduced maintenance needs, to gain a clear understanding of their value.

Understanding the specific strengths and limitations of semi-pneumatic tires allows you to make a choice that fits your operational demands. This careful evaluation ensures your selection aligns with both budgetary and performance goals.

How to Get Started with Semi-Pneumatic Tires

Starting with semi-pneumatic tires involves understanding your equipment's needs. First, review your equipment's manual to find the recommended tire sizes. Accurate measurements of existing tires are important to ensure compatibility and proper fit.

Opt for complete wheel assemblies to make installation straightforward and efficient. Having extra sets available for vital machinery can prevent interruptions and keep operations running smoothly.

It's also crucial to check the load capacity of the tires. Match these ratings with your equipment's weight requirements to maintain safety and performance. Evaluating costs against pneumatic alternatives helps in making an informed decision that aligns with your budget.

Semi-pneumatic tires offer a practical solution for equipment owners who value reliability and low maintenance over maximum cushioning. By understanding their unique benefits and limitations, you can make an informed decision that keeps your equipment running smoothly without the hassle of constant tire maintenance.

Ready to explore tire options that match your specific needs? We make it easy to shop for tires online and find the best deals with our extensive selection and expert guidance to help you choose the perfect tires for your vehicle or equipment.

Ready to find the perfect tires?

Search By