Tire News & Information

Free shipping

Best price guarantee

SimpleCrew exclusive savings

0% financing options

Tire replacement coverage

24/7 roadside assistance

Easy returns

Pneumatic tires are a common sight on vehicles of all types, from everyday cars to heavy-duty industrial equipment. They play a crucial role in providing a smooth, comfortable ride and ensuring optimal performance in various applications.

While most people are familiar with pneumatic tires, many may not fully understand how they work or what sets them apart from other tire types. Gaining a basic knowledge of pneumatic tires can help vehicle owners make informed decisions when purchasing new tires or maintaining their current set.

In this article, we'll dive into the world of pneumatic tires, exploring their definition, key characteristics, and common applications. By the end, you'll have a solid understanding of what pneumatic tires are and why they are so widely used.

What Are Pneumatic Tires?

Pneumatic tires are rubber tires that use compressed air to maintain their shape and provide cushioning. They are the most common type of tire found on a wide range of vehicles, including cars, trucks, forklifts, and other industrial equipment.

The word "pneumatic" comes from the Greek word "pneuma," which means air or breath. This is fitting, as the defining characteristic of a pneumatic tire is the pressurized air contained within its inner core. This air pressure allows the tire to support the weight of the vehicle while absorbing shocks and providing a smooth ride.

Key Components of a Pneumatic Tire

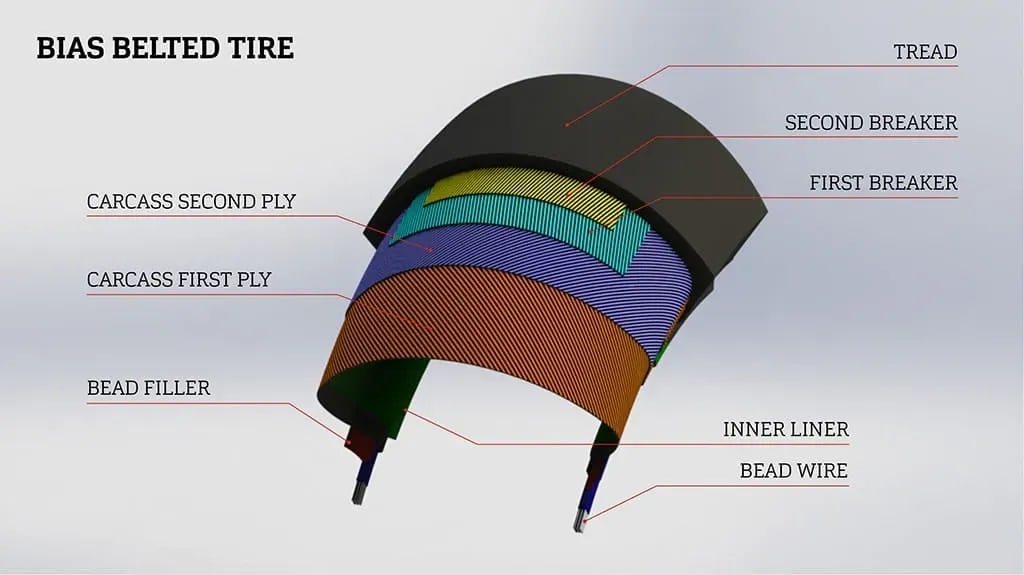

A typical pneumatic tire consists of several key components:

- Tread: The outer surface of the tire that comes in contact with the road, providing traction and handling.

- Sidewall: The visible part of the tire between the tread and the wheel rim, containing important information such as tire size, load capacity, and speed rating.

- Belts: Layers of steel or fabric located beneath the tread that provide strength and stability to the tire.

- Plies: Layers of fabric that form the tire's internal structure, running from bead to bead and providing additional strength and support.

- Beads: The inner edges of the tire that sit securely on the wheel rim, ensuring an airtight seal.

- Inner Liner: A layer of airtight rubber that holds the compressed air inside the tire.

These components work together to create a tire that can withstand the demands of various driving conditions while providing a comfortable and safe ride.

Advantages of Pneumatic Tires

Pneumatic tires offer several key benefits that contribute to their widespread use:

- Shock Absorption: The compressed air inside the tire acts as a cushion, absorbing shocks and vibrations from the road surface. This results in a smoother, more comfortable ride for passengers and helps protect the vehicle's suspension components from excessive wear.

- Traction: The tread patterns on pneumatic tires are designed to provide optimal traction on a variety of surfaces, including wet and dry roads, gravel, and even light off-road conditions. This improves safety and handling, especially during acceleration, braking, and cornering maneuvers.

- Versatility: Pneumatic tires are available in a wide range of sizes, tread patterns, and load capacities, making them suitable for various vehicle types and applications. From high-performance sports cars to heavy-duty construction equipment, pneumatic tires can be tailored to meet specific needs.

- Cost-Effective: Compared to solid or foam-filled tires, pneumatic tires are generally less expensive to manufacture and replace. This makes them a more budget-friendly option for vehicle owners, especially those who need to replace tires frequently due to high mileage or demanding driving conditions.

While pneumatic tires offer many advantages, it's essential to understand their limitations and potential drawbacks, such as susceptibility to punctures and the need for regular maintenance. In the following sections, we'll explore these aspects in more detail, providing a comprehensive overview of pneumatic tires and their applications.

How Do Pneumatic Tires Work?

Pneumatic tires utilize a design centered around an airtight chamber filled with air under pressure. At the core of each tire lies a sealed cavity, crafted to contain this pressurized air, which is essential for the tire’s shape and function. This internal air pressure exceeds the pressure of the surrounding atmosphere, a crucial factor in the tire's capacity to operate effectively.

This difference in pressure between the tire's interior and the outside environment enables the tire to support the vehicle's mass and any additional loads it carries. The pressure ensures that the tire maintains its form, allowing it to handle various driving conditions without deforming. Consequently, pneumatic tires are capable of bearing significant loads, delivering a stable and reliable driving experience.

With the pressurized air acting as a cushion, the tire efficiently absorbs road shocks and adapts to surface irregularities. This flexibility is vital for preserving traction and stability across a range of terrains—from smooth city streets to rougher rural roads. The design of pneumatic tires ensures they can adjust to different surfaces, providing both durability and a comfortable ride for vehicle occupants.

Advantages of Pneumatic Tires

Pneumatic tires excel in their ability to adapt to different terrains, offering a driving experience that is both smooth and controlled. Their design includes a flexible air-filled structure that efficiently absorbs the impact from rough surfaces. This feature allows for seamless travel over rocky paths, uneven dirt roads, and grassy fields, ensuring that both drivers and passengers enjoy a steady and comfortable ride despite the challenging landscape.

Beyond comfort, pneumatic tires provide exceptional grip and balance across a variety of surfaces. The enhanced stability these tires offer is crucial for maintaining control during sharp turns or sudden stops, thereby improving overall vehicle safety. With their ability to maintain traction under diverse conditions, pneumatic tires help prevent skidding, ensuring drivers have the confidence to navigate different environments.

Furthermore, the availability of varied tread patterns means pneumatic tires can be tailored to specific needs, whether for off-road exploits or city commutes. This adaptability allows them to perform effectively in various applications, showcasing their versatility. Additionally, pneumatic tires are often more affordable than their solid or foam-filled counterparts, providing an economical option for vehicle owners seeking reliable performance without incurring high costs.

Disadvantages of Pneumatic Tires

Despite their many advantages, pneumatic tires have certain limitations that need consideration. A primary issue is their vulnerability to punctures. Sharp objects like nails or debris can easily breach the tire, causing air to escape and leading to potential delays. This tendency to get flats can cause unexpected interruptions, which is particularly challenging for commercial vehicles or those operating on tight schedules.

Moreover, pneumatic tires are not always suited for indoor environments. Their tendency to bounce can lead to discomfort and fatigue for operators who work long hours in confined areas. This bouncing can also decrease handling precision, making it less favorable for tasks that demand exact control, such as navigating forklifts in a warehouse. Additionally, the continuous bouncing can gradually increase wear on the vehicle's suspension and other parts.

Pneumatic tires also require regular upkeep to function effectively. Consistent monitoring of tire pressure is crucial, as improper inflation can affect fuel efficiency and safety. Under-inflation can lead to poor handling, while over-inflation reduces traction and accelerates wear. Neglecting these maintenance tasks can result in uneven tread wear and shorter tire lifespan, ultimately increasing costs. This need for ongoing attention can be a drawback compared to solid or foam-filled tires, which typically demand less frequent care.

Common Applications for Pneumatic Tires

Pneumatic tires are engineered to thrive in challenging environments, making them a staple in outdoor settings. Their robust construction and design enable them to effectively tackle the rugged conditions commonly found on construction sites. With their ability to deliver reliable traction and stability, these tires ensure that heavy machinery can operate smoothly and safely, even amidst debris and uneven surfaces.

Industries like logging and lumber require equipment to perform on a variety of ground conditions, from dirt trails to rocky paths. Pneumatic tires, with their capacity to absorb impacts and maintain grip, are well-suited for such demanding tasks. They provide the necessary support for vehicles like skidders and loaders, ensuring that operations continue efficiently without compromising safety or performance.

When it comes to heavy-duty vehicles, pneumatic tires offer indispensable support. Forklifts used in outdoor environments benefit from the enhanced traction these tires provide, which is crucial for maneuverability and load stability. In agriculture, tractors and other machinery frequently encounter soft, variable terrain, and pneumatic tires offer the durability and operator comfort needed for effective operation. This makes them an ideal choice for applications that demand resilience and adaptability under diverse conditions.

Factors to Consider When Choosing Pneumatic Tires

When selecting pneumatic tires, it's essential to assess the environment where they will be used. Different settings call for varying tire characteristics to ensure they meet performance and durability needs. For example, tires with deeper treads might be necessary for outdoor use on uneven or rough terrains to enhance grip, while smoother indoor surfaces could benefit from a design that reduces friction and noise.

Another important factor is the tire's ability to support the vehicle's load. The selected tires should handle the vehicle's weight and any additional cargo, ensuring that they perform well under various driving conditions, such as turning and stopping. Choosing tires with the right load capacity is critical for maintaining vehicle stability and safety.

Operator comfort is paramount, particularly for vehicles in continuous use. Reducing vibrations and providing a smooth ride can decrease operator fatigue and enhance efficiency. The tire's design and structure play roles in absorbing road impacts, contributing to better comfort and handling.

Lastly, the specific tread pattern and material composition of the tires should align with the operational needs. Different jobs may require unique tread designs—some may need robust patterns for off-road traction, while others benefit from a less aggressive design for paved surfaces. The tire's material should withstand the specific wear and tear of the environment while ensuring safety and performance.

Pneumatic Tire Maintenance and Best Practices

Ensuring the longevity and performance of pneumatic tires requires diligent maintenance. Begin with regular tire pressure checks, adhering closely to the manufacturer's guidelines for inflation levels. Proper inflation not only enhances road contact for improved handling but also ensures vehicle stability. Utilizing an accurate tire pressure gauge can help prevent the adverse effects of incorrect inflation, such as uneven wear and reduced fuel efficiency.

Routine inspections are vital for maintaining tire health. Examine tires for any visible damage like cuts, punctures, or sidewall abnormalities that could affect their performance. Identifying uneven tread wear early can highlight alignment or suspension issues that need attention. Additionally, clearing out any embedded debris helps prevent potential damage that might compromise tire integrity over time.

Implementing a tire rotation schedule is crucial for even tread distribution, which in turn prolongs tire life. Following the manufacturer's rotation recommendations ensures balanced wear across all tires, which enhances overall vehicle performance and safety. Regular rotations, when combined with periodic balancing and alignment, form a comprehensive tire care strategy, minimizing the risk of unexpected tire issues and ensuring a smooth, safe ride.

As you embark on your journey to understand and select the right pneumatic tires for your needs, remember that proper maintenance and attention to key factors will ensure optimal performance and longevity. At SimpleTire, we are committed to providing you with the knowledge and tools necessary to make informed decisions about your tire purchases. Shop for tires online and let us help you find the best deals on the perfect set of pneumatic tires for your vehicle.

The pneumatic rubber tires were first patented by Robert W. Thomson, a Scottish engineer. However, the tire became popular only in 1888 when John Boyd Dunlop invented the pneumatic tires for the second time.

No, while some modern passenger and light-duty truck tires are pneumatic, they can also be semi pneumatic and non pneumatic tires.

Ready to find the perfect tires?

Search By